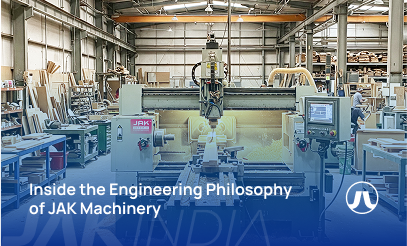

Inside the Engineering Philosophy of JAK Machinery

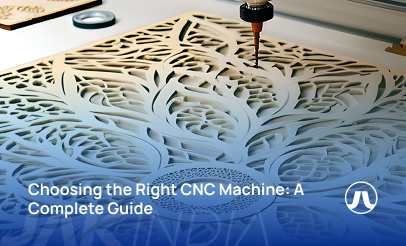

Explore how CNC machines are revolutionizing traditional woodworking across India. From reducing manual effort to increasing precision and scalability, this blog breaks down the real impact of automation for carpenters, furniture makers, and small manufacturers.