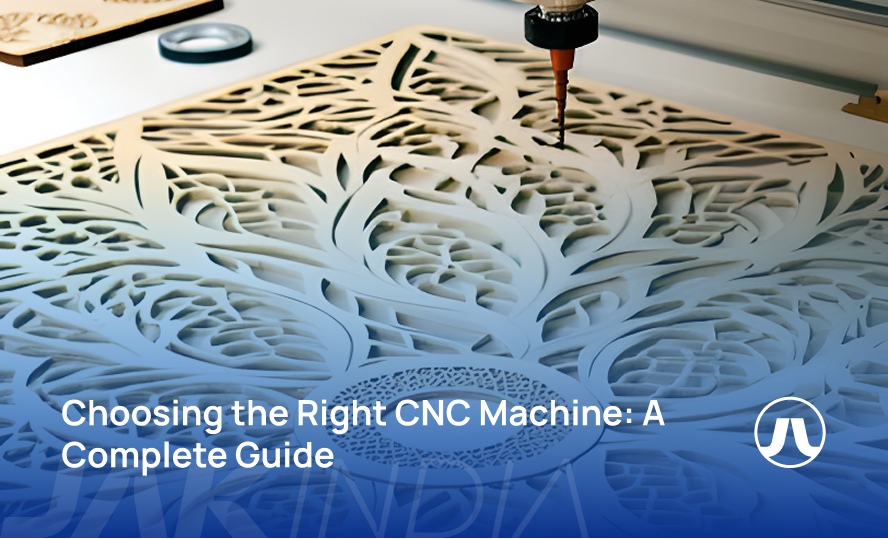

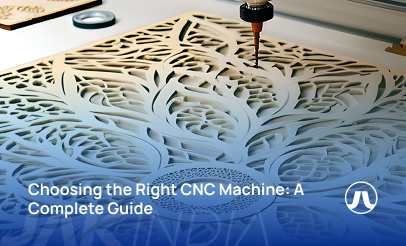

How to choose CNC Wood lathe Model

Choosing the right CNC wood lathe depends on your specific woodworking needs, the complexity of your designs, and the types of products you want to create. This guide outlines the different types of CNC wood lathe machines based on the number of axes they use and what each type can do.