CNC stone router is a computer-controlled machine designed for cutting, carving, engraving, and shaping various types of stone, such as granite, marble, and quartz. Also Wood, MDF, PVC, ACP etc. It ensures high precision and efficiency in creating intricate designs, sculptures, countertops, and architectural elements. Ideal for both industrial and artistic applications, CNC stone routers enhance productivity while maintaining consistent quality.

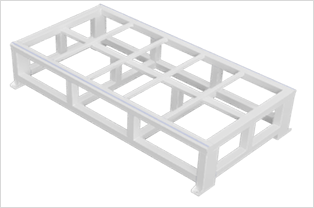

Robust bed structure than wood router with corrosion resistance material because of tool coolant waterflow

Keeping Spindle cooled using industrial water chiller with water flow sensor

Easy Bed Cleaning to remove stone residuals and filtering the water

| Operations | Stone and Non metal material carving |

| Bed Size | 4x8 Feet (customizable) |

| Max Material Thickness | 3 inch (Customizable) |

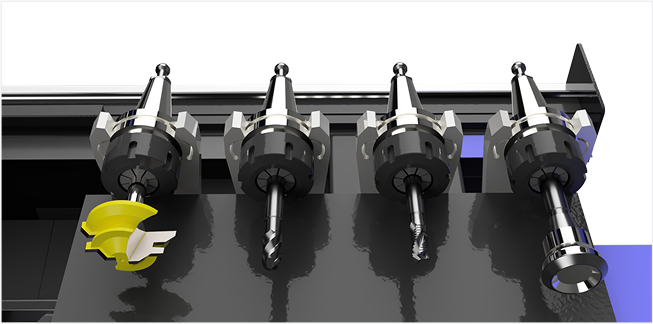

| Carving Spindle Type | MTC (Manual Tool Change) |

| Spindle Specification | 5.5/6 kW Air Cooled, 24000 rpm, ER32 |

| Bed Type | T-Slot Aluminum waterbed |

| Axis Motion Motor | Servo Motor |

| Max Rapid Speed | 14000 mm/min |

| Position Accuracy | 0.05 mm (50 Micron) |

| Number of Axis | 3 Axis |

| Controller | NK105 / Mach3 LAN |

isolating the control drives from the power source

Showing the Machine position if running, Stops or Emergency State

Navigate the Oil from Pump to Rail Bearings in one minute

Connected Heavy duty Fabricated Base Structure

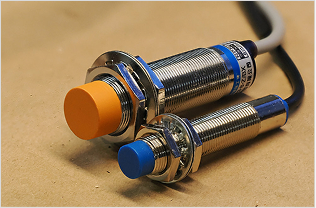

PnF Make High Quality Sensors

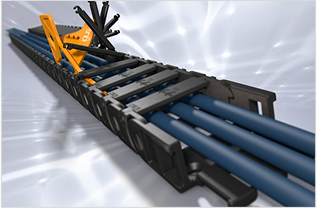

High Quality Flxible Cable for 10 million Cycles

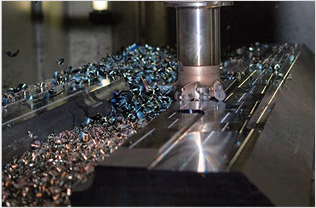

Our over important Plates passed with VMC Milling and Drilling

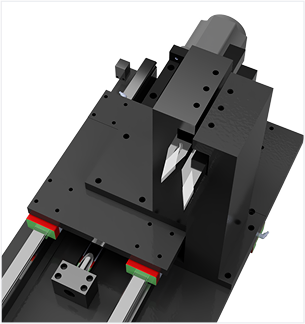

High precision Gearbox for high rigidity on fast movement

Automatic On off Dust hood during the operation

That keep water under temperature range to protect spindle from heating

JAK Special Design through our rich experience to clean the bed in few minutes

Double Production using two separate Spindle head.

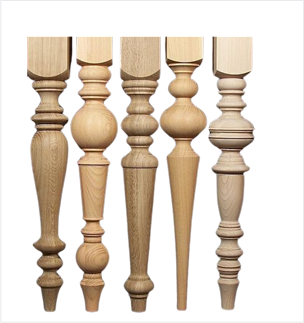

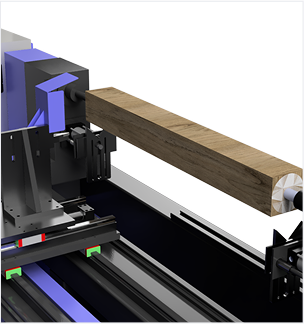

Rotary Stone Pilar Carving

Managed by: littlebig.in